Why is Radiant Heater Material Important?

We exclusively use Extruded Aluminum to form the backbone of our heaters.

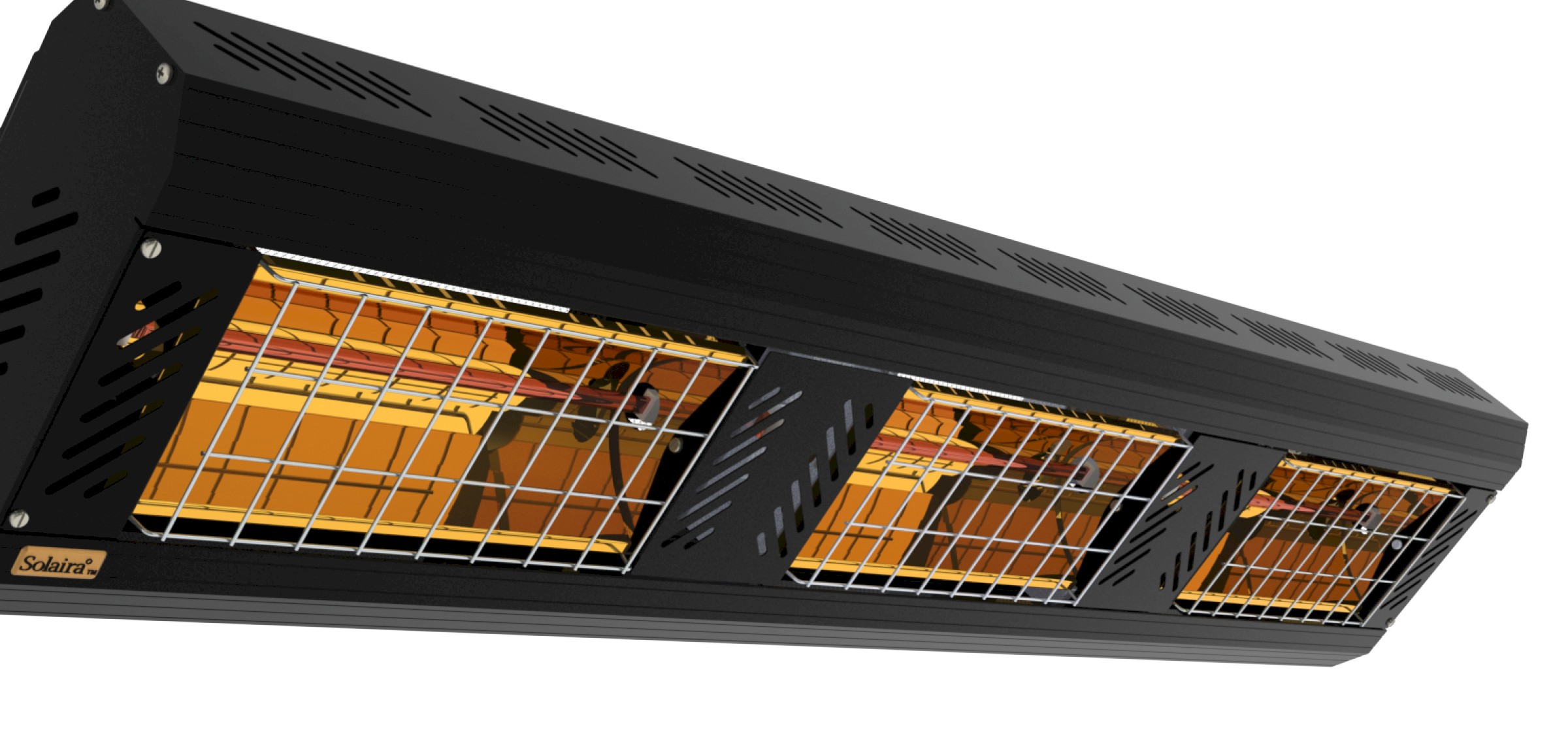

We often refer to our products as “infrastructure grade”. We take pride in producing the most robust radiant heater chassis in the market. How do we do this? The secret is in our heater body materials and construction. We exclusively use Extruded Aluminum to form the backbone of our heaters. Extruded aluminum has a wide range of excellent material properties, from its strength and malleability to its high thermal conductivity. Properties like these allow us to optimise heater design for longevity.

Fixture Robustness

As a base material, Aluminum is relatively high strength and stiffness. While not as strong or as stiff as steel or stainless steel, Aluminum is more malleable and can be forced into intricate shapes. Metal extrusion allows us to form complex shapes and profiles, similar to the lighting industry. Aluminum extrusion also allows us to increase the wall thickness of our fixtures, leading to a stiffer structure when completely assembled. This is important in demanding environments with high winds.

Heat-shedding capacity

Aluminum has an excellent capacity to shed heat. It has a thermal conductivity between 5-20x higher than steel and stainless steel – meaning our fixtures have an excellent ability to shed heat that builds up inside the fixture. This is important when designing for longevity. Keeping the emitters and electrical components cool is critical in extending the lifespan of the heater. Additionally, over thousands of heating and cooling cycles our fixture will resist warping or distortion - a common issue with heaters that use steel or stainless steel in their construction. Our products do not use fiber insulation or any insulating material to protect our electrical components – simply due to the fact that we use Aluminum.

Corrosion resistance

The most common corrosion is rust – a common sight for painted or galvanized steel components that are exposed to years of environmental stressors. Aluminum does not rust – bare aluminum that is exposed to air reacts with oxygen, forming a protective aluminum oxide layer which resists any corrosion. If our fixtures are scratched or abraded a new protective film will form, preventing corrosion. Unlike its name, Stainless Steel does not mean “no stain” – it simply means greater rust resistance. Stainless Steel does rust – especially in the presence of salt which is transferred into the air in seaside environments. Aluminum has significantly higher resistance to corrosion in seaside environments – Aluminum will eventually corrode, but it requires an extremely corrosive environment.

Solaira, ICR Series H2, Joe Byrne Memorial Stadium, Grand Falls-Windsor, NL

Solaira, XL Slim Series H1, De Dutch Restaurant, Vancouver, BC